You are here : Home | Products & Systems | Water Softeners | Salt Free Systems | Anti Scale Systems | OneFlow Pre Carbon + Anti-Scale

[one_fourth padding=”0 6px 0 0″]

![]()

OneFlow Models

[su_spacer]

General Information

About OneFlow® Scale Control Systems

OneFlow® vs Conventional Softening

[su_spacer]

Model Range Information

[su_spacer]

[su_spacer size=”430″]OneFlow Series – Pre Carbon + Anti-Scale

Series Model OF210-1, OF220-2 and OF240-4

Series Model OF210-1, OF220-2 and OF240-4

OneFlow ® Anti-Scale System

Connection Sizes: 1⁄2″ and 3⁄4″ (15 and 20mm)

Flow Rates: From 0.5 gpm to 4 gpm (1.9 lpm to 15.2 lpm)

The OneFlow® Anti-Scale System with two filter housings provides protection from scale formation and reduces chlorine and other off tastes to improve overall water quality in Food Service applications. The OneFlow® system is a dual cartridge-based system that may be installed on a cold water line prior to a water-using device (coffee maker, espresso machine, post-mix system or other appliance) that requires protection from the ill effects of hard water. OneFlow® works exceptionally well where the water is being heated or brought to steam. OneFlow® prevents scale by transforming dissolved hardness minerals into harmless, inactive microscopic crystal particles. These crystals stay suspended in the water and are passed to drain, thereby having a greatly reduced ability to react negatively like dissolved hardness does. The system requires very little maintenance, no backwashing, no salt, and no electricity. Typical hardness problems, especially build-up of scale in heating elements, boilers, and steamers, are no longer a concern.

OneFlow® is not a water softener. It does not add chemicals or remove any minerals. It is a scale prevention device with proven third party laboratory test data and years of successful Food Service and Commercial applications. OneFlow® is the intelligent scale solution with chlorine reduction as a great alternative to water softening (ion exchange) or scale sequestering devices.

Features

[one_half]- Chemical free scale prevention and protection – converts hardness minerals to harmless, inactive microscopic crystals making OneFlow® effective alternative technology to a water softener for the prevention of scale due to water hardness and for the reduction of chlorine for better taste and odour

- Virtually maintenance free – No salt bags or other chemicals to constantly add or maintain

- Uses environmentally friendly “green” technology

- Improves efficiency of all water appliances whether heating the water or not

- Simple sizing & installation – all you need to know is pipe size and flow rate

- No control valve, no electricity and no wastewater

- Perfect system for restaurants, cafeterias and coffee shops where multiple or single equipment protection is desired for longer equipment life and reduced energy consumption

- Inlet ball valve for easy isolation shutoff and filter changes

- OneFlow® does not remove the essential minerals in water that are linked to good health

- OneFlow® cartridge-based systems are easily maintained; change the carbon cartridge every 6 months and the OneFlow® media cartridge once per year.

| Models | ||

|---|---|---|

| Model | Maximum Flow Rate | Connection Sizes |

| OF210 – 1 | 1 gpm (4 lpm) | 1⁄2” (15mm) FNPT |

| OF220 – 2 | 2 gpm (8 lpm) | 1⁄2” (15mm) FNPT |

| OF240 – 4 | 4 gpm (15 lpm) | 3⁄4” (20mm) FNPT |

| Replacement Cartridge | |

|---|---|

| OF110RM | Cartridge should be replaced every 12 months |

| OF120RM | Cartridge should be replaced every 12 months |

| OF140RM | Cartridge should be replaced every 12 months |

| OF110RC | Cartridge should be replaced every 6 months |

| OF120RC | Cartridge should be replaced every 6 months |

| OF140RC | Cartridge should be replaced every 6 months |

* The wetted surface of this product contacted by consumable water contains less than one quarter of one percent (0.25%) of lead by weight.

For hot water applications where water temperature is 110°F – 150°F (43°C – 66°C), please consult ES-OneFlow-Hot Water.

Specifications

A OneFlow® scale prevention system with added carbon filtration shall be installed on the cold water service line to condition and filter the tap water just prior to the service line feeding the equipment it is designed to protect. The system will be sized for maximum or peak flow rate based on the specification of said equipment. A OneFlow® system with added carbon filtration may also be installed to protect multiple pieces of equipment from the ill-effects of hard water scale and taste/odour concerns provided the aggregate peak flow rate for each piece of equipment it is protecting has been considered. The system shall be plumbed with a bypass valve to allow isolation of filter housings to allow the bypass of untreated water in the event that service or cartridge replacement is necessary. The installation area should be suitable in size for the housing to be serviced without encumbrance and the system should be installed per the Installation, Operation & Maintenance manual as provided with each system.

The OneFlow® system must not require additional waste water to backwash, flush, or regenerate once put into service. The system shall not require any chemical additives and shall not require electricity for operation.

Note: Copper lines need to be passivized for a minimum of 4 weeks before placing unit into service. Not for use on closed loop systems.

| Water Chemistry & Limitations | |

|---|---|

| pH | 6.5 to 8.5 |

| Hardness (maximum) | 75 grains (1300 ppm CaCO3) |

| Temperature | 41°F to 100°F (5° to 38°C) |

| Chlorine | < 3ppm |

| Iron (maximum) | 0.3 mg/l |

| Manganese (maximum) | 0.05 mg/l |

| Copper | none allowed |

| Oil & H2S | none allowed |

| Polyphosphate | none allowed |

| Silica (maximum) | 10 ppm |

Standards

Independent scientific testing has confirmed Template Assisted Crystallization (TAC) technology provides scale reduction of over 95+%. Testing was conducted under protocol based on DVGW W512 test to access control of scale formation.

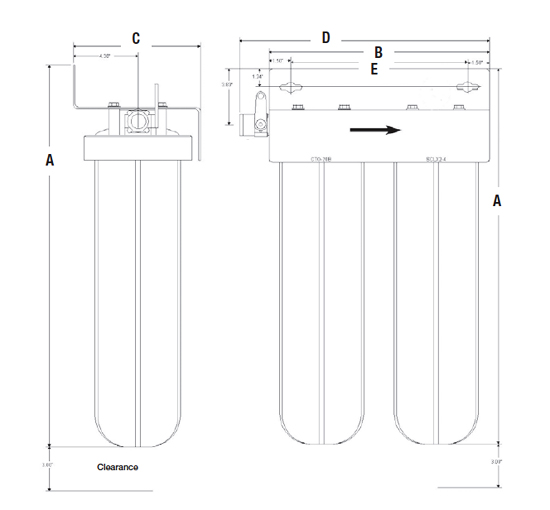

| Dimensions | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C* | D | E* | ||||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | lbs | kgs | |

| OF210-1 | 141⁄2 | 37 | 91⁄4 | 24 | 51⁄8 | 13 | 111⁄4 | 29 | 53⁄4 | 15 | 9 | 4.1 |

| OF220-2 | 241⁄2 | 62 | 91⁄4 | 24 | 51⁄8 | 13 | 111⁄4 | 29 | 53⁄4 | 15 | 14 | 6.4 |

| OF240-4 | 26 | 66 | 151⁄4 | 39 | 85⁄8 | 22 | 175⁄16 | 44 | 121⁄4 | 31 | 31 | 14.1 |

The overall height and the height of the fitting varies due to material variations and assembly tolerances. Please allow additional clearances above the tank for making connections.

[/three_fourth_last]

Series Model OF210-1, OF220-2 and OF240-4

Series Model OF210-1, OF220-2 and OF240-4