HOME | STORAGE TANKS | SECTIONAL TANKS

We offer sectional tanks that are made from hot pressed moulded panels to British and European Standards. Although there is no gel coat, the isophthalic resin rich inner surface is ideal for storing wholesome water. WRAS approved products.

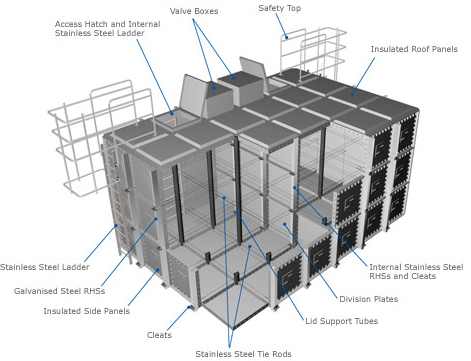

Tanks constructed from panels can be built in spaces with restricted access.

Panels

Panel sizes currently offered are:

1 metre square

1 metre by 1/2 metre

1/2 metre by 1/2 metre

All sizes are available either plain or 40mm pre-insulated.

Access Hatches

All tanks come with a raised access hatch which is secured by 4 stainless steel fixings with a special finger-friendly top to enable the access hatch to be opened. To complete the requirement a seal is located on the underside of the access. This seals the top from the ingress of dirt and moisture. The access can be modified to be hinged and lockable, if required.

Raised Ball Valve Box “AA” and “AB” Air Gaps

To maximise capacity or to offer a type “AA” or “AB” air gap, a valve box can be included in the lid, thereby allowing a valve with a drop arm or an Aylesbury KA/KB valve to be fitted. The standard valve boxes for sectional tanks are 300mm in height with other heights available on request. When a type “AB” air gap is needed, a slot is cut in the tank (of a size dependant on inlet valve size), covered with a specially moulded shroud that incorporates a screened mesh, and with a catchment tank that can then be plumbed into a discharge overflow. For type “AA” air gap the screened mesh is omitted.

Divisions

Tanks can be divided into compartments with stainless steel internal RHSs and cleats. Any divided section of a tank should not remain empty for more than 7 days to preserve the torque setting of the structure.

Insulation

Pre-insulated panels use zero ozone depletion polyurethane foam which is then covered with a waterproof skin. Phenolic foam insulation is also available to special order.

Fittings

A wide range of fittings is available to suit these tanks. See our fittings section for more details

Ladders

Both internal and external ladders are constructed from 316-grade stainless steel to recognised standards in terms of physical performance and size. Ladders are fitted by our assembly crews in their required position. Our ladders are also offered as a separate item. See our Tank Ladders section for more details.

Safety Railings

IWE offers a unique design in stainless steel safety railings to be fitted around the top perimeter of tanks. Our safety railings adhere to British Standards in terms of performance and are lightweight and easily assembled on-site. The fitting of safety railings is advised by the HSE on tanks of 2 metres and above in height.

Base Requirements

It is important to ensure that the base on which the sectional tank sits is flat, level and able to take the weight of the structure and its contents when full, without deflection. There are three base options on which sectional tanks can be assembled:

- Option 1 – Steels

- Option 2 – Brick/concrete piers

- Option 3 – Flat concrete base

The centres of the steels or piers MUST comply with our base requirements.

For tanks up to 1 metre high we require supports at 1 metre centres. Tanks of 1%uFFFD metres high or more should have supports at %uFFFD metre centres. We do offer higher tanks at 1 metre centres but will modify the bracing system to accommodate this. Correct base detail is very important in order to optimise the tank’s long-term performance. The offer of a free site survey will ensure that the base is correct.

Bracing System

When bracing our sectional tanks, we use stainless steel fixings throughout including tie rods inside the tank, and galvanised box section steel externally at every joint on tanks over 1 metre high.

Joints and Mechanical Fixings

The material used in jointing the panels is WRAS approved and has proven not to contaminate the contents. There is resistance in the material which will prevent it from being excessively squeezed out of the joint. Each bolt is coated with a special material when the assembly takes place to prevent water from running along the thread.

Assembly

Although we do offer specific assembly instructions for sectional tanks we would always recommend that our trained tank assembly crews are employed to complete the assembly.

Following the site survey our assembly crews can be booked for a specific day. We will advise you of the time required to complete the job, which allows you to put this into your programme of works.

60 to 99 ltr

100 to 199 ltr

200 to 299 ltr

300 to 399 ltr

400 to 499 ltr

500 to 599 ltr

600 to 699 ltr

700 to 799 ltr

800 to 999 ltr

1000 to 1199 ltr

1200 to 1499 ltr

1500 to 1999 ltr

2000 to 2999 ltr

3000 to 3999 ltr

4000 to 5499 ltr

5500 to 5999 ltr

6000 to 6999 ltr

7000 to 7999 ltr

8000 to 8999 ltr

9000 to 9999 ltr

10,000 to 11,999 ltr

12,000 to 14,999 ltr

15,000 to 16,999 ltr

20,000 to 24,999 ltr

Over 25,000 ltr