You are here : Home | Spares & Parts | Controllers | Ultrafiltration Controllers | UFS8000

Ultrafiltration Controllers

| MODEL SELECTION | |||

| UF3020 | UF2050 | ||

| UFS8000 | |||

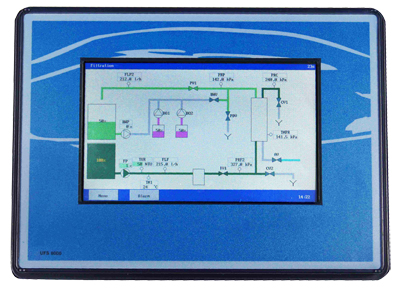

Ultrafiltration Controller – UFS8000

[one_half padding=”0 10px 0 0″][su_note note_color=”#7e7e7e” radius=”10″]Download Manual[/su_note][/one_half] [one_half_last padding=”0 0px 0 0″][/one_half_last] [su_spacer size=”30″]

| Cooling Tower Controller – AS3020 (1 conductivity meter, man. Temp. Comp. 4 inputs and 3 outputs). | |

| Model | Power in / out |

| AS3020-1 | 24/24, 115/115 or 230/230 VAC |

| AS3020-2 | 115/24 or 230/24 VAC |

| Cooling Tower Controller – AS3020IF (1 conductivity meter, man. Temp. Comp. 5 inputs and 5 outputs). | |

| AS3020IF-1 | 24/24, 115/115 or 230/230 VAC |

| AS3020IF-2 | 115/24 or 230/24 VAC |

Description

Features

- Choice of languages (English, French, German, Dutch and Russian).

- Graphic TFT display (800×480, touch panel) with easy to use menu

- Adaptable to user specific requirements by built-in programmable options.

- Universally applicable for various sizes of installation.

- Treated water production controllable by hand or level switches.

- Programming a service telephone number possible.

- Substantial status information: actual input and output conditions, service telephone number, alarm history, software version

- Security of program information against supply failure.

- 8x Outputs (powered) programmable for output function e.g. inlet valve, feed pump, backwash pump, concentrate valve, permeate valve, dosing pumps.

- 6x Outputs (potential free) programmable for output function e.g. inlet valve, feed pump, backwash pump, concentrate valve, permeate valve, dosing pumps.

- 8x inputs (digital contacts) (optional up to 24) : stop, high level switch, low level switch, valve position switch, pump protection switch, exceeded pressure switch, external alarm reset switch, start backwash, start filtration, level switch dosing tank.

- Option : up to 6 Recorder outputs 0(4)-20mA for recording measurements

- Option : up to 12 Inputs 0(4)-20mA for flow meters, pressure meters, conductivity meters and tank level measurement

- SD Card functions for software updates, data log and loading and saving of configuration.

- Option : RS232 and RS485 communication for log data

- Option : Ethernet communication for web server, e-mail function and remote control

- Enclosure suitable for wall mounting, panel mounting and plate mounting

- Available supply voltage (input/output) : 24-240V, 115/24V, 230/24V and 240/24V.