HOME | REVERSE OSMOSIS | INDUSTRIAL REVERSE OSMOSIS | HERCO | KR & KRFU RANGE

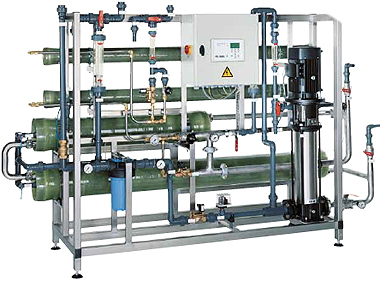

KR & KRFU - SERIES 1

Stand-type unit for desalination of softened drinking water according to German drinking water regulations (free chlorine not detectable), operating on the principle of reverse osmosis, with very high permeate recovery up to 90 % due to additional concentrate stage and high salt rejection up to 98.5 %. With controller RO 5000 and horizontal 8‘‘ membranes as well as concentrate rinsing unit, connection set for manual cleaning device.

Stainless steel main frame housing the instruments and controls. Special inlet filter with 5 μm-filter cartridge, high pressure pump low noise (incl. frequency converter for KR/FU systems), multi-stage centrifugal type, specially combined spirally wound modules with PA/PS composite membranes in GRP vessels with inliner.

| KR/FU 3000 Technical Data | ||

| Permeate flow rate | l/h | 3,000 |

| Min. salt rejection | % | 98,5 |

| Recovery | % | 85 |

| Operating pressure | bar | 18,5 |

| Membrane element / number | 4040 / 12 | |

| Voltage | V/Hz | 3 x 400 V / 50 |

| Motor power | kW | 5.5 |

| Pre-fusing | A | 16 |

| Feedwater connection | DN | 32 |

| Permeate / concentrate connection | DN | 25/ 25 |

| Conductivity permeate | μS/cm | 2 – 200 |

| Cond. permeate recirculation | μS/cm | 20 - 2,000 |

| Height | mm | 1,650 |

| Width | mm | 3,550 |

| Depth | mm | 700 |

| Weight approx | kg | 400 |

| Code no. | 381827 | |

| KR/FU 3500 Technical Data | ||

| Permeate flow rate | l/h | 3,500 |

| Min. salt rejection | % | 98,5 |

| Recovery | % | 85 |

| Operating pressure | bar | 18 |

| Membrane element / number | 4040 / 14 | |

| Voltage | V/Hz | 3 x 400 V / 50 |

| Motor power | kW | 5.5 |

| Pre-fusing | A | 16 |

| Feedwater connection | DN | 32 |

| Permeate / concentrate connection | DN | 25/ 25 |

| Conductivity permeate | μS/cm | 2 – 200 |

| Cond. permeate recirculation | μS/cm | 20 - 2,000 |

| Height | mm | 1,650 |

| Width | mm | 3,550 |

| Depth | mm | 700 |

| Weight approx | kg | 450 |

| Code no. | 381837 | |

Description

Stainless steel main frame housing the instruments and controls. Special inlet filter with 5 μm-filter cartridge, high pressure pump low noise (incl. frequency converter for KR/FU systems), multi-stage centrifugal type, specially combined spirally wound modules with PA/PS composite membranes in GRP vessels with inliner. Valves such as sampling valves for feed water and permeate (for each pressure vessel), KR-permeate recirculation, inlet solenoid/diaphragm valve, valves made of stainless steel to regulate the flow rate of permeate, concentrate and concentrate recirculation. Pressure gauges for inlet and outlet pressure pre-filter, pump pressure, operating pressure and concentrate pressure, pressure switch for monitoring the feed water pressure. Flow meters for permeate, KR-permeate recirculation, concentrate and concentrate recirculation flow rate. Conductivity measurement permeate and KR-permeate recirculation, temperature compensated, measuring ranges 2-200 μS/cm and 20-2,000 μS/cm. Connection set for manual cleaning device and concentrate flushing device Control cabinet with lockable main switch, electrical switchgear for control of the high-pressure pump. Unit is completely wired, pre-assembled and ready for installation. Electrical equipment in accordance with VDE 0100 part 600, VDE part 1. Compressed air (oil-free) 4-6 bar required from UO 7000 KR onwards.

RO 5000 microprocessor control system

For fully automated monitoring and control of the reverse osmosis unit with graphics display with scrollable display (selectable) of operating data: permeate- and feed-water conductivity (temperature compensated), permeate- and feed-water temperature, operating hours, time malfunction signals: low pressure, hard water, motor overload, high conductivity prealarm (permeate), high conductivity fault (permeate), status signals: operation, permeate discard/ permeate recycling, concentrate displacement, concentrate rinse, intermittent rinse during shut down, shut down by external signal (forced stop, regeneration), tank full, LEDs for operation, malfunction. Chip card reader for storage of parameters and data (1 chip card is included in our scope of delivery), RS232 interface. Additional connections possible: Inputs (low voltage) for level control with 1 or 2 float switches, hardness monitoring unit (the RO 5000 control system includes control functions for the limitron hardness monitoring unit), shut-down by external signal (forced stop, regeneration. Outputs additional pump (in series or duty/ standby) for 2 solenoid valves for concentrate rinse, permeate discard and recycling, collective malfunction, prealarm high conductivity and freely programmable universal output each on floating changeover contact, analogue output of permeate conductivity and permeate temperature (4-20 mA).

The units are designed for a maximum TDS of 1,000 mg/l, a max. SiO2-concentration of 10 mg/l, a water temperature of 15°C, a maximum colloidal index of 3 and free permeate outlet. Under these conditions, the units still reaches design permeate flow after three years of operation. The permeate recovery depends on the raw water quality and the type of pre-treatment.

KR & KRFU - SERIES 2

KR and KR/FU – 4000–10000 l/h RO Systems with special concentrate stage. Stand-type unit for desalination of softened drinking water according to German drinking water regulations (free chlorine not detectable), operating on the principle of reverse osmosis, with very high permeate recovery up to 90 % due to additional concentrate stage and high salt rejection up to 98.5 %.

Stainless steel main frame housing the instruments and controls. Special inlet filter with 5 μm-filter cartridge, high pressure pump low noise (incl. frequency converter for KR/FU systems), multi-stage centrifugal type, specially combined spirally wound modules with PA/PS composite membranes in GRP vessels with inline.

| KR/FU 4000 Technical Data | ||

| Permeate flow rate | l/h | 4000 |

| Min. salt rejection | % | 98,5 |

| Recovery | % | 85 |

| Operating pressure | bar | 16 |

| Membrane element / number | 8040 / 3+ 4040 / 4 | |

| Voltage | V/Hz | 3 x 400 V / 50 |

| Motor power | kW | 7.5 |

| Pre-fusing | A | 20 |

| Feedwater connection | DN | 32 |

| Permeate / concentrate connection | DN | 32 / 32 |

| Conductivity permeate | μS/cm | 2 – 200 |

| Cond. permeate recirculation | μS/cm | 20 - 2,000 |

| Height | mm | 1,900 |

| Width | mm | 2,800 |

| Depth | mm | 700 |

| Weight approx | kg | 520 |

| Code no. | 381847 | |

| KR/FU 5000 Technical Data | ||

| Permeate flow rate | l/h | 5000 |

| Min. salt rejection | % | 98,5 |

| Recovery | % | 85 |

| Operating pressure | bar | 15,5 |

| Membrane element / number | 8040 / 4+ 4040 / 4 | |

| Voltage | V/Hz | 3 x 400 V / 50 |

| Motor power | kW | 7.5 |

| Pre-fusing | A | 20 |

| Feedwater connection | DN | 40 |

| Permeate / concentrate connection | DN | 32 / 32 |

| Conductivity permeate | μS/cm | 2 – 200 |

| Cond. permeate recirculation | μS/cm | 20 - 2,000 |

| Height | mm | 1,900 |

| Width | mm | 2,800 |

| Depth | mm | 750 |

| Weight approx | kg | 570 |

| Code no. | 381857 | |

| KR/FU 6000 Technical Data | ||

| Permeate flow rate | l/h | 6000 |

| Min. salt rejection | % | 98,5 |

| Recovery | % | 87 |

| Operating pressure | bar | 15 |

| Membrane element / number | 8040 / 5+ 4040 / 5 | |

| Voltage | V/Hz | 3 x 400 V / 50 |

| Motor power | kW | 7.5 |

| Pre-fusing | A | 20 |

| Feedwater connection | DN | 40 |

| Permeate / concentrate connection | DN | 40 / 32 |

| Conductivity permeate | μS/cm | 2 – 200 |

| Cond. permeate recirculation | μS/cm | 20 - 2,000 |

| Height | mm | 1,900 |

| Width | mm | 3,800 |

| Depth | mm | 750 |

| Weight approx | kg | 680 |

| Code no. | 381867 | |

| KR/FU 7000 Technical Data | ||

| Permeate flow rate | l/h | 7000 |

| Min. salt rejection | % | 98,5 |

| Recovery | % | 90 |

| Operating pressure | bar | 15 |

| Membrane element / number | 8040 / 6+ 4040 / 6 | |

| Voltage | V/Hz | 3 x 400 V / 50 |

| Motor power | kW | 7.5 |

| Pre-fusing | A | 20 |

| Feedwater connection | DN | 40 |

| Permeate / concentrate connection | DN | 40 / 32 |

| Conductivity permeate | μS/cm | 2 – 200 |

| Cond. permeate recirculation | μS/cm | 20 - 2,000 |

| Height | mm | 1,900 |

| Width | mm | 3,800 |

| Depth | mm | 750 |

| Weight approx | kg | 800 |

| Code no. | 381877 | |

| KR/FU 8500 Technical Data | ||

| Permeate flow rate | l/h | 8500 |

| Min. salt rejection | % | 98,5 |

| Recovery | % | 90 |

| Operating pressure | bar | 16 |

| Membrane element / number | 8040 / 7+ 4040 / 7 | |

| Voltage | V/Hz | 3 x 400 V / 50 |

| Motor power | kW | 11.0 |

| Pre-fusing | A | 25 |

| Feedwater connection | DN | 50 |

| Permeate / concentrate connection | DN | 40 / 32 |

| Conductivity permeate | μS/cm | 2 – 200 |

| Cond. permeate recirculation | μS/cm | 20 - 2,000 |

| Height | mm | 1,900 |

| Width | mm | 4,800 |

| Depth | mm | 750 |

| Weight approx | kg | 900 |

| Code no. | 381887 | |

| KR/FU 10000 Technical Data | ||

| Permeate flow rate | l/h | 10000 |

| Min. salt rejection | % | 98,5 |

| Recovery | % | 90 |

| Operating pressure | bar | 15 |

| Membrane element / number | 8040 / 9+ 4040 / 9 | |

| Voltage | V/Hz | 3 x 400 V / 50 |

| Motor power | kW | 11.0 |

| Pre-fusing | A | 25 |

| Feedwater connection | DN | 50 |

| Permeate / concentrate connection | DN | 50 / 32 |

| Conductivity permeate | μS/cm | 2 – 200 |

| Cond. permeate recirculation | μS/cm | 20 - 2,000 |

| Height | mm | 2,000 |

| Width | mm | 3,900 |

| Depth | mm | 1000 |

| Weight approx | kg | 1050 |

| Code no. | 381897 | |

Description

Stainless steel main frame housing the instruments and controls. Special inlet filter with 5 μm-filter cartridge, high pressure pump low noise (incl. frequency converter for KR/FU systems), multi-stage centrifugal type, specially combined spirally wound modules with PA/PS composite membranes in GRP vessels with inliner. Valves such as sampling valves for feed water and permeate (for each pressure vessel), KR-permeate recirculation, inlet solenoid/diaphragm valve, valves made of stainless steel to regulate the flow rate of permeate, concentrate and concentrate recirculation. Pressure gauges for inlet and outlet pressure pre-filter, pump pressure, operating pressure and concentrate pressure, pressure switch for monitoring the feed water pressure. Flow meters for permeate, KR-permeate recirculation, concentrate and concentrate recirculation flow rate. Conductivity measurement permeate and KR-permeate recirculation, temperature compensated, measuring ranges 2-200 μS/cm and 20-2,000 μS/cm. Connection set for manual cleaning device and concentrate flushing device Control cabinet with lockable main switch, electrical switchgear for control of the high-pressure pump. Unit is completely wired, pre-assembled and ready for installation. Electrical equipment in accordance with VDE 0100 part 600, VDE part 1. Compressed air (oil-free) 4-6 bar required from UO 7000 KR onwards.

RO 5000 microprocessor control system

For fully automated monitoring and control of the reverse osmosis unit with graphics display with scrollable display (selectable) of operating data: permeate- and feed-water conductivity (temperature compensated), permeate- and feed-water temperature, operating hours, time malfunction signals: low pressure, hard water, motor overload, high conductivity prealarm (permeate), high conductivity fault (permeate), status signals: operation, permeate discard/ permeate recycling, concentrate displacement, concentrate rinse, intermittent rinse during shut down, shut down by external signal (forced stop, regeneration), tank full, LEDs for operation, malfunction. Chip card reader for storage of parameters and data (1 chip card is included in our scope of delivery), RS232 interface. Additional connections possible: Inputs (low voltage) for level control with 1 or 2 float switches, hardness monitoring unit (the RO 5000 control system includes control functions for the limitron hardness monitoring unit), shut-down by external signal (forced stop, regeneration. Outputs additional pump (in series or duty/ standby) for 2 solenoid valves for concentrate rinse, permeate discard and recycling, collective malfunction, prealarm high conductivity and freely programmable universal output each on floating changeover contact, analogue output of permeate conductivity and permeate temperature (4-20 mA).

The units are designed for a maximum TDS of 1,000 mg/l, a max. SiO2-concentration of 10 mg/l, a water temperature of 15°C, a maximum colloidal index of 3 and free permeate outlet. Under these conditions, the units still reaches design permeate flow after three years of operation. The permeate recovery depends on the raw water quality and the type of pre-treatment.

Herco KR and KRFU Range

Stand-type unit for desalination of softened drinking water according to German drinking water regulations (free chlorine not detectable), operating on the principle of reverse osmosis, with very high permeate recovery up to 90 % due to additional concentrate stage and high salt rejection up to 98.5 %.