Uncategorized

Preventing RO Membrane Fouling: A Comprehensive Guide

Preventing RO Membrane Fouling

Reverse osmosis (RO) membranes are critical components in water filtration systems, effectively removing contaminants and impurities. However, over time, these membranes can become fouled, leading to decreased efficiency and increased operating costs. Here we will explore the various causes of RO membrane fouling and provide practical tips to prevent it, ensuring optimal performance and longevity of your water purification system.

Understand the Causes of Fouling:

Understand the Causes of Fouling:

To effectively prevent RO membrane fouling, it’s important to familiarise yourself with the common causes:

- Scaling: Mineral deposits such as calcium, magnesium, and silica can accumulate on the membrane surface, reducing its permeability

- Biological Growth: Bacteria, algae, and fungi can thrive in the water system, forming biofilms on the membrane and obstructing water flow

- Particulate Matter: Suspended solids, sediment, and fine particles can clog the membrane pores, causing fouling

- Organic Fouling: Dissolved organic compounds, oils, and greases can foul the membrane by adsorbing onto the surface or penetrating its pores

Regular Maintenance: Implementing a proactive maintenance routine is crucial to prevent RO membrane fouling. Consider the following measures:

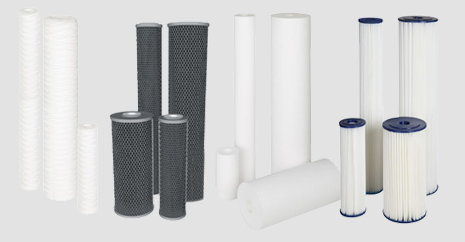

- Pre-Treatment: Install appropriate pre-treatment systems like sediment filters, activated carbon filters, and water softeners to remove particulate matter, chlorine, and other contaminants before water reaches the RO membrane

- Regular Cleaning: Develop a cleaning schedule based on manufacturer guidelines. Use approved cleaning solutions and follow proper procedures to remove accumulated deposits and organic matter

- Monitor System Parameters: Keep a close eye on feed water pressure, temperature, and flow rates. Deviations from optimal operating conditions can contribute to fouling

- Replace Pre-Filters: Replace pre-filters at recommended intervals to prevent excessive particulate matter from reaching the membrane.

Control Feed Water Quality:

Taking steps to maintain high-quality feed water can significantly reduce the likelihood of membrane fouling:

- Analyse Water Composition: Conduct periodic water quality analysis to identify the presence of scaling minerals, organic compounds, or biological contaminants. Adjust pre-treatment methods accordingly

- pH Adjustment: Maintain appropriate pH levels to minimise the risk of scaling and ensure the membrane operates within the recommended range

- UV Disinfection: Implement a disinfection strategy to control biological growth. UV sterilisation or chlorination can effectively mitigate the risk of biofilm formation

- Filtration: Consider additional filtration techniques such as micro filtration or ultrafiltration to remove suspended solids and larger particles

Operator Training and Awareness:

Empower your system operators with knowledge and training to understand the importance of preventing membrane fouling

- Proper Handling: Train operators on the correct handling and storage of cleaning chemicals, avoiding contamination or damage to the membranes

- Routine Inspections: Encourage regular visual inspections of the membrane to detect any signs of fouling, such as discolouration, biofilm, or reduced permeate quality

- Record-Keeping: Maintain detailed records of maintenance activities, cleaning schedules, and any observed changes in system performance. This information can aid in troubleshooting and fine-tuning your preventive measures

The take away…

Preventing RO membrane fouling requires a combination of proactive maintenance, effective pre-treatment, and diligent system monitoring. By understanding the causes of fouling and implementing preventive measures, you can ensure the long-term efficiency and performance of your water purification system. Regular maintenance, control of feed water quality, and operator training are key elements in maintaining clean and productive RO membranes.

Remember, prevention is always better than cure when it comes to RO membrane fouling. Invest time and effort into preventive measures to save costs and membrane lifespan, and enjoy consistently high-quality water. Industrial Water Equipment Ltd (IWE) is a trusted and reliable resource for addressing all your RO membrane needs. With our extensive knowledge and expertise in water treatment solutions, we are dedicated to providing exceptional support and assistance. We offer a comprehensive range of high-quality RO membranes from reputable manufacturers, ensuring that you have access to the best products for your specific application. Our team of experienced professionals is available to provide technical guidance, troubleshooting support, and tailored solutions to optimise the performance of your RO membrane system. Whether you require maintenance services, membrane cleaning, replacement, or performance evaluations, we have you covered. Our commitment to customer satisfaction means you can rely on their timely and responsive support whenever you need it. With IWE as your partner, you can trust that your RO membrane needs are in capable hands, ensuring efficient and reliable water treatment processes.