HOME | WASTEWATER & RECYCLING | PACKAGED SYSTEMS | CONTAINERISED SYSTEMS

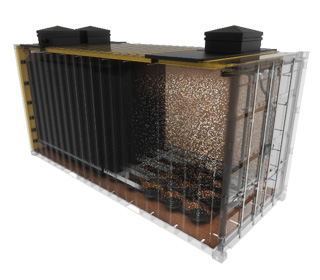

A containerised mobile waste water treatment plant is a packaged system where all wastewater treatment equipment is completely preinstalled in ISO shipping containers.

The modular container system with the various components of a waste water plant are adjusted to customer requirements and can be easily transported by land and sea. As all the waste water treatment equipment is preinstalled and factory tested, onsite installation work is limited and basically Plug & Play.

Application Size:

There is no limit or restriction on the size of the project that our containerised systems

can be utilised for, as the system is modular.

Waste water treatment systems from 50 to 20.000 persons, or 8-800m3 of wastewater per day have been commissioned. For larger applications it may become more financially viable to make use of SBR equipment solutions in tanks and structures that are constructed onsite. Any effluent quality can be achieved.

Advantages of a ClearFox® packaged wastewater treatment:

-

Market leading, state of the art technology is built into our container solutions, which are manufactured in a quality controlled environment and are factory tested.

-

The complete system with all its components is provided from one supplier, thus limiting financial risk.

-

It is made in Germany, with 20 years warranty on new packaged waste water treatment systems.

-

The waste water container treatment plants are suitably designed for all climate zones and achieve maximum efficiency in each process step.

-

The system can easily be transported by land or sea and is easily setup in isolated remote and off the grid areas.

-

Low costs for scheduling and construction, as no infrastructure or buildings are required. Only a solid base or foundation is needed on which to place the containers.

-

The solution is modular, fully automatic plug & play and can be tailored to the specific local conditions and project requirements.

-

Rapid installation and setup of the system as it is delivered with all equipment preinstalled. Simply connect the system to the electricity supply, then connect the inlets and outlets.

-

It can be rapidly dismantled to be quickly and easily relocated to a new location.

-

Low energy costs due to the integrated energy saving mode.

-

Imperceptible noise as the entire container treatment plant is enclosed.

-

Standard, locally obtainable spare parts can be used for maintenance, thus saving time and money.

-

Can be used as a fixed or temporary solution for any existing treatment plant, in a supporting function, during improvements being undertaken [new, upgrade, bypass].

-

The modules can be added on to upgrade existing WWTPs to meet new emission limits.

-

It is flexible, as systems can be designed as complete waste water treatment plants or hybrid systems, depending on the requirements.

-

Designed for waste water treatment, sludge treatment and industrial water treatment for different medium and large scale applications such as the food industry or for remote communities without access to a municipal sewage system.

Applications

- Industrial waste water treatment solutions for any industrial wastewater [food, drink, dairy, auto, etc]

- Municipal: during upgrade or maintenance work on existing sewage treatment plants

- Communal: remote communities without access to a municipal sewage system

- Replacement or relief overflow of pond treatment plants

- For regional tourist facilities to provide extra capacity

- Complete solutions for medium scale applications such as hotels, resorts, housing developments, schools, hospitals, etc.

Remote tourist facilities, lodges, camping sites and military camps. - Refugee, asylum and worker camps

- Offshore applications eg. on oil rigs

- mobile solutions for remote construction sites, drilling and mining sites

- Agricultural: Treatment of slurry and digestate from Biogas plants

- Emergency wastewater treatment following catastrophes and disasters

- Infrastructure for large events

- Temporary solutions, rented sewage treatment plants, leased sewage treatment plants

- In connection with portable toilets or washroom container

- Specialist industrial wastewater solutions and pilot scale WWTPs for non standard applications [landfill, oil and gas, power plants, etc]

How does a mobile waste water container work?

The different containerised wastewater treatment modules used depend on the specific project requirements and the effluent standards that need to be achieved.

Mechanical pretreatment of the raw wastewater is accomplished by the use of a screw screen. Theses screens remove large inorganic particles from the wastewater. Compact screens can be used to remove grease and sand [or other coarse aggregates] where necessary. These mechanical screens can be mounted on the containerised wastewater treatment plant or can be installed within the packaged plant.

Inorganic waste material removed by the screen is collected and removed offsite for disposal or further treatment. In smaller wastewater treatment plants, mechanical pretreatment can be integrated by the use of primary settlement tanks, in which case the inorganic materials are then not separated but collected along with the primary sludge for disposal.

Buffering may be required after the mechanical screening. We can distinguish between the different types of wastewater buffering as follows:

-

Aerated buffering for the breakdown of simple carbon based compounds

-

Unventilated buffering, for the sole purpose of managing hydraulic peak flows

-

Anoxic buffering which can be required for pre-denitrification or selection processes in industrial wastewater treatment.

Most complete packaged containerised wastewater treatment systems are a combination of several stages of treatment. Where large buffering is required then the use of concrete or plastic tanks can be incorporated into the design.

Fully automatic mobile waste water treatment systems

The operation of the containerised waste water treatment plant is completely automatic and requires only a minimum of operator input. With integrated energy saving modes the mobile wastewater treatment plant can adapt to the actual volume of wastewater entering the system. This makes our packaged waste water treatment plants highly energy efficient resulting in reduced operation and maintenance.

Contact us for a free quotation

Do you have a question or need more information about a sewage treatment plant? We shall be happy to develop a suitable solution to your specific requirements.

Please call us on 01629 363311 or use the form below.

CONTACT US

- 1 PE tank 2250 litres, (sludge storage and buffer) individual weight: approx: 120 kg; dimensions lxwxh 1535mm x 1215mm x 1710mm

- 1 PE tank 2250 litres, (biology reactor) individual weight: approx: 170 kg; dimensions lxwxh 1535mm x 1215mm x 1710mm

- Required base area: 3.10m x 1.22m

- Max. inlet depth: 1000mm below area surface

- Access opening tank: 600mm

- Plant size: 4 PE (residents)

- Outlet values: Class C (according to German classification)

Additional options ClearFox nature:

- Manhole pit extension (attachment tube)

- Manhole pit extension (extendable manhole pit, also available as drive-in)

- Pump shaft DN600

- Sewage handling pump 230V

- Flotation safeguard (protection against all refloating)

- 2 PE- container 2250 litre/liter, ( sludge storage and buffer) individual weight: ca. 120 kg measurement: lxbxh 1535x1215x1710mm

- 1 PE-container 2250 Liter, ( bioreactor ) individual weight ca. 170 kg Abmessung: measurement lxbxh 1535x1215x1710mm

- required base area 4,70×1,22m

- inlet depth: 1000mm under ground surface

- manhole container: 600mm

- plant size: 8 EW inhabitants

- discharge parameters: Class C according to German classification, nitrification

Additional options clearfox nature:

- manhole pit(Aufsatzrohr) Attachment pipe/ tube

- manhole pit extensions also available.

- pumping chamber DN600

- sewage pump/wastewater pump 230V

- floating prevention

- 4 PE-Container 2250 Liter, sludge storage and buffer individual weight ca. 120 kg measurement: lxbxh 1535x1215x1710mm

- 2 PE-Container 2250 Liter, ( bioreactor ) individual weight: ca. 170 kg Abmessung: lxbxh 1535x1215x1710mm

- required base area: ~ 6,10×2,80m

- inlet depth: 1000mm under ground surface

- manhole container: 600mm

- plant size: 16EW inhabitants

- discharge parameters: Class C according to German classification, nitrification

Additional options for clearfox nature:

- manhole pit extensions also available.

- manhole pit Attachment pipe/ tube

- pumping chamber DN600

- sewage pump/wastewater pump 230V

- floating prevention

Wastewater Packaged Systems

Sewage treatment systems pre-assembled at the factory and tested according to the European standard 12566-3 and 12566-6.