You are here : Home | Products & Systems | Water Filters | UV Water Filters | IWE Range | ST08

[one_fourth padding=”0 6px 0 0″]

![]()

IWE UV Water Filters

SDE Range

[su_spacer]

ST08 Range

[su_spacer]

SPS Range

[su_spacer size=”100″][/one_fourth] [three_fourth_last padding=”0 0px 0 0″]

ST08 Range Installation Manual & Operating Instructions

| IWE ST08 RANGE | |||

| ST08 Range UV Water Filters | ST08 Range UV Filter Kits | ||

| Installation Manual | CE Certificate | ||

| Dimensions | |||

Installation, Operation and Maintenance Manual

For IWE ST08 Series Ultraviolet Disinfection Water System

[su_spacer]

| Risk of severe or fatal electrical shock when water is in close proximity to this electrical system. User must always disconnect power before performing any maintenance on this system. | |

| This UV system must be grounded. | |

| Always wear protective eye and skin wear. Germicidal ultraviolet rays are harmful to the eyes and skin, exposure should be avoided. | |

| CAUTION: Risk of burning due to heat from the lamp when in use. Never touch the lamp directly; we advise always wearing protective gloves. |

Thank you for purchasing an Industrial Water Equipment ultraviolet disinfection water system. This manual will help you get the very best from your new system. It covers the installation, operation and maintenance of your new UV system.

PLEASE READ ALL THE INSTRUCTIONS CAREFULLY BEFORE BEGINNING TO INSTALL OR TURN ON THE EQUIPMENT. THIS IS TO KEEP YOU AND THE EQUIPMENT SAFE.

Application of product

UV water systems are increasingly popular, highly effective, and one of the easiest ways to protect your water from living organisms. Used worldwide by domestic, commercial and industrial customers uv water treatment is now one of the most trusted, quicker and healthier methods of water treatment compared with older less efficient methods.

What is Ultraviolet light and how does it work?

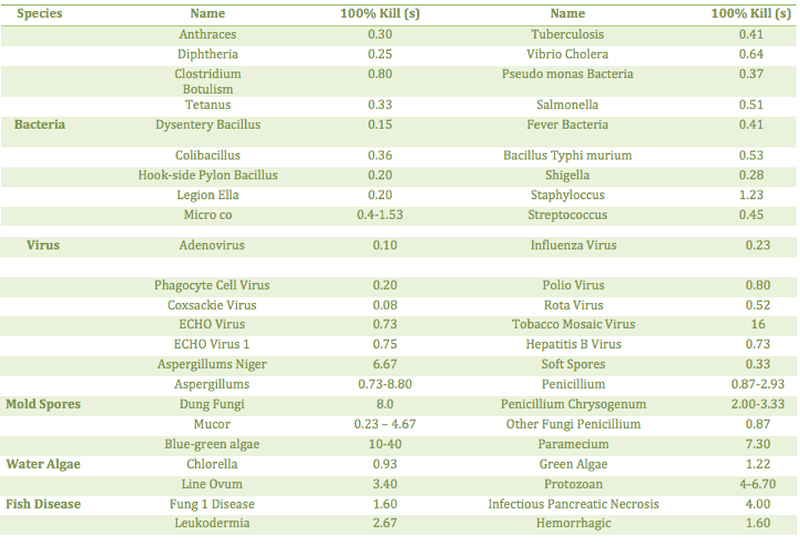

Ultraviolet light is a type of electromagnetic radiation such as radio waves, infrared, x-rays etc. UV light has wavelengths ranging from 100 to 400 nanometers (nm). The UV spectrum is divided into four different regions, which are designated Vacuum UV, UV-A, UV-B, and UV-C. UV-C or short-wave ultraviolet occurs between 200-280nm and the optimum UV germicidal action at 265nm. UV light has a useful and strong disinfection ability, which can physically eradicate microorganisms by altering their DNA or RNA, which is done effectively and without the use of chemicals.

CAUTION:

Because ultraviolet light is not visible to the human eye, we can sometimes ignore it is there, however UV light is harmful to eyes and skins and therefore exposure should be taken very seriously.

Industrial Water Equipment’s UV Systems use Philips Ultraviolet Lamps, which highly and effectively discharge a germicidal UV-C ray (253.7nm) to disinfect the water by killing all bacteria, viruses, molds and algae. With proper implementation of an IWE In-line UV System, any of these small organisms can be completely destroyed fast without any harmful residuals.

Advantages of a UV System

Effective

UV application is much more effective that chlorination and other disinfection water systems on a large amount of pathogens. UV light prompts a reaction that is almost instant at destroying the dangerous pathogens.

Harmless and Chemical-free

UV light does not alter the water chemistry or its components, such as taste, odor, colour or PH level etc. It also does not involve adding chemicals to you water therefore keeping you water chemical free and healthy for you and your family.

Low Cost

Initial outlay and operating costs are low in comparison to other disinfection methods available.

Simple to install and operate

UV systems do not have any moving parts, which are prone to wearing out and are easy to install wherever required.

Water Quality Guidelines for your IWE UV

Our IWE UV water systems are only intended for use with obviously clear water, not tainted, slightly coloured, murky, unclear or turbid.

- Ambient Water Temperature: 2-45º

- Iron: <0.3ppm (0.3mg/l)

- Hardness: <7gpg (120mg/l)

- Turbidity: <1NTU

- Manganese: 0.05ppm (0.05mg/l)

- UV Transmittance: >75%

IWE Product Specification

The IWE UV Water System range is available in a variety of sizes and can be used to purify the water for a single tap or for the entire home or large building.

The IWE UV is simple and safe equipment that is suitable for small residential applications and large commercial projects.

IWE UV Installation

- All our units are quality tested in the factory.

- All of our IWE units are rated up to 12bar.

- IWE UV’s must be installed vertically or horizontally on a firm and level surface.

- IWE UV’s must not be placed on the ground or where water may pool.

- Do not submerge your IWE UV.

- Must be in a readily accessible, well-lit location to allow for inspection and maintenance.

Always allow space around the UV to change the UV Lamp and Quartz Sleeve. The suggested space should be equal to the overall length of you IWE UV.

Installation Instructions

Step 1:

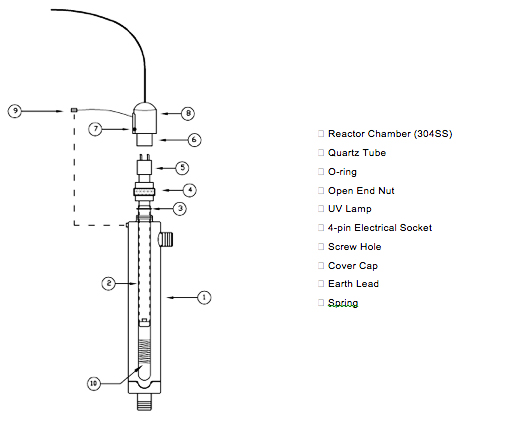

Check you have all the correct components:

- Reactor Chamber

- UV Lamp

- Quartz Sleeve

- O-ring

Electronic Ballast and Support.

Step 2:

Ensure the quartz sleeve and UV lamp are thoroughly clean before starting to install. This can be done with alcohol or a mild detergent. Always wear soft non-abrasive gloves to keep any finger marks away from them.

Step 3:

Remove the end nut from the Reactor Chamber.

Step 4:

Insert the spring into the quartz sleeve.

Step 5:

Install the O-ring onto the open end of the quartz sleeve.

Step 6:

Insert the quartz sleeve into the Reactor Chamber.

Step 7:

Hand-screw the end nut onto the Reactor Chamber. In order to protect the O-ring, do not over tighten.

Step 8:

Connect the 4-pin electrical socket with the UV lamp pins tightly.

Step 9:

Very carefully insert the quartz sleeve through the end nut onto the UV lamp

Step 10:

Put the cover cap onto the end Nut.

Step 11:

Insert the earth cable tightly.

Step 12:

Carefully tighten the screw.

Step 13:

You can install your IWE UV horizontally or vertically.

Select the location that the UV will be placed; it must be easily accessible and well lit. Your IWE UV should always be located to the nearest point of use.

Step 14:

Once all plumbing work is complete, slowly turn on the water and check for leaks.

Step 15:

It will take a few minutes for the water to clear any air or dust that might have been in the reactor chamber, so allow the water run for a few minutes.

Step 16:

Connect the power supply

IWE UV Operations

- Double-check the installation before you plug the IWE UV into the power supply.

- IWE UV’s are especially designed for continuous operation. Frequently switching it on and off will reduce the UV’s radiation and life span. Your IWE UV must not be switched on and off more than three times in a 24-hour period.

- In the event that your IWE UV should fall into water, turn off the power immediately at the mains and then remove from the water. DO NOT use your IWE UV if it has been submerged in water.

- DO NOT operate your IWE UV if the cord or plug is damaged, the unit has been dropped or if it starts to malfunction.

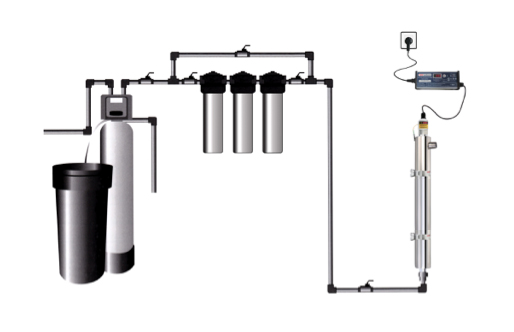

- 5. Install your IWE filter on the return line. This will guarantee that the water does not have any debris or impurities that could prevent the disinfection process. You can install your IWE UV before the filter, however this will cause it to take longer to work efficiently, while increasing the risk of breaking lamp and/or the quartz sleeve.

- UV rays are dangerous and can cause damage to eyes and skin. Appropriate measures should be taken to prevent injury. Always wear safety goggles and never look directly at the UV light or remove it whilst in operation.

- DO NOT exceed the maximum flow rate; if this is possibility install a flow regulator at the inlet in order to protect the quartz sleeve.

- The water supply must always be disconnected and your IWE UV completely drained of water if there is risk of freezing for an extended period of time.

How to disinfect your plumbing system

UV sterilisation is a physical disinfection process that does not add any potentially harmful chemicals into your water system, because UV sterilisation does not provide any disinfection residual, it is essential that all your plumbing after the UV be chemically disinfected. This will guarantee that the water will be free from any bacterial contaminants. The decontamination process must be done as soon as you install the UV and repeated whenever the UV has to be shut down for any reason.

Disinfection process:

- Turn off the upstream water supply that feeds the reactor chamber and then depressurise water system.

- Remove the pre-filter cartridge and then add 250-500ml of household bleach or chlorine (5.25%) into the empty filter housing (DO NOT use hydrogen peroxide) and re-attach.

- Check that the Aqua-lite ultraviolet system is connected to the AC power supply and operating correctly.

- Open all taps, fittings and appliances. Let the cold water run until you can smell the bleach. Then turn off the water and leave the bleach water sit in the pipework for about thirty to sixty minutes. You must make sure that any appliance attached to the plumbing system passes chlorinated water including taps inside and out, washing machines, dishwashers, toilets, shower heads, water heaters etc.

- Now re-open the upstream water supply and put the filter cartridge back into the filter. Then flush the chlorine solution completely from the system until you cannot smell bleach anymore.

DO NOT drink the water in the system during this process, as there are very high concentrations of chlorine in the water.

In the event that a your IWE UV should be shut down for routine cleaning or during power cut where water could have passed through the system, the above procedure must also be followed.

Maintenance

General Maintenance

- Test before each use or monthly.

- It is recommended that the lamp should be replaced every 9000 hours that is in use, it may still radiate light however the UV intensity will not be as effective.

- Clean the quartz sleeve once every 3-6 months, you can use either a mild detergent or alcohol.

Replacement of lamp

CAUTION: DO NOT touch the lamp without gloves on, handle only by the ends or wear soft gloves to prevent any fingermarks on the lamp.

- You will not need to turn off the water supply to do this.

- Turn off the main power and let the unit power down, this should take about 30 seconds.

- Remove the cover cap.

- Remove the lamp wire carefully until there is about 2 inches of the lamp visible. Take care, as the lamp case can be very hot; be careful not to drop the lamp on the quartz sleeve, as both are very delicate and will break easily.

- Remove the 2-pin electrical socket, holding tightly onto the Aqua-lite ultraviolet lamp.

- Remove quartz sleeve from the lamp very carefully, these are incredibly delicate! The best way to do this is to pull it out at a straight not at an angle until it is completely out.

- To reinstall the lamp follow steps 7 to 11

NOTE: When you have replaced the lamp, remember to reset the lamp life timer.

How to replace the quartz sleeve

- Turn the off at the power supply

- Turn off the water supply to your IWE UV’s inlet and outlet valves.

- Remove the drain plug and drain the chamber, once this is done remove any old Teflon tape from the drain plug threads. With new Teflon tape, rewrap the drain plug and re-install and tighten the drain plug.

- To remove the UV lamp, follow the ‘replacement lamp’ steps as above.

- Unscrew the nuts off the reactor chamber.

- Remove the O-ring

- To remove the quartz sleeve from the chamber carefully rotate it and extract.

- Clean the quartz sleeve with a mild detergent or alcohol, for stubborn stains you can use a diluted hydrochloric acid wash.

- In the event that the quartz sleeve is broken, the following steps must be followed before re-installing:

- Take out the input/output water pipe connector and remove from the chamber.

- Remove as much of the broken glass as possible from both ends of the chamber.

In order to remove any tiny fragments from the chamber, you will need hold the system vertically and shake. This will cause the fragments from the threaded fitting to break and fall out. Flush the chamber system with water and carefully to remove all the glass fragments from the inside the chamber.

Throw away all pieces of the broken glass

- To re-install the quartz:

- Step 4: Insert the spring into the quartz sleeve.

- Step 5: Install the O-ring onto the open end of the quartz sleeve.

- Step 6: Insert the quartz sleeve into the Reactor Chamber.

- To re-install the new lamp see the lamp installation instructions.

- Slowly restore the water supply to your aqua-lite UV and check for leaks.

- Turn on power.

FAQ’s

To help you keep your IWE UV in optimum operation condition see our most popular FAQ’s. Should a specific problem arise during the routine inspection, please refer to the maintenance instructions.

| FAQ'S | Possible Causes | Solutions |

|---|---|---|

| Drop in pressure | Pre filter clogged | Replace filter cartridges |

| High bacteria count | Quartz sleeve is stained or dirty | Clean the Quartz sleeve |

| Feed water quality changed | Have raw äter tested to ensure that water quality is still within bounds | |

| Contamination in water after UV system | It is imperative the the effluent water stream be shocked with chlorine (bleach) before water leaves the UV system-disinfection system must have a bacterial free distribution system to work effectively. | |

| Possible breakthrough of sediment through pre-filter | Have source water tested for turbidity. Use cartridges with higher filtration precision. | |

| Heated product water | Common problem caused by infrequent use of water. | Run water until it returned to ambient temperature. |

| Water appears milky | Caused by air in the water lines | Run water till air is purged |

| Unit leaking at end caps | Problem with o-ring | Ensure o-ring is in place; clean and then re-install ; replace them if necessary. Do not use a pipe wrench, pliers or any other tool. Hand tighten only, do not use lubricant. |

| Unit leaking at inlet or outlet opening | Inadequate inlet/outlet port connection | Check the thread connections, reseal with Teflon tape and re-tighten. |

| Moisture inside the quartz sleeve | Quartz sleeve is broken or cracked. | Visual inspect the Quartz sleeve. If broken or cracked replace. |

| System shutting down intermittently | Interrupted power supply | Ensure the system is installed on its own circuit as other equipment may be drawing power away from the UV (i.e pump or fridge) |

| Lamp failure alarm on (new Lamp) | Moisture build up in connector may keep lamp and socket from making a solid connection | Eliminate chance of any moisture getting to the socket and / or lamp pins. |

IWE UV Spare Parts

Philips Bulbs

Your IWE UV is supplied with a Philips bulb, Philips are well known as one of the largest manufacturers of high quality, standard low-pressure mercury lamps. Philips TUV lamps comprise of a tubular glass envelope, which emit a short-wave UV radiation. (Peak at 254 nm (UVC) for germicidal action) These in-house built glass filters out the 185 nm ozone forming line thus preventing the creation of ozone. A protective coating on the inside of the bulb limits the depreciation of the useful UVC output; this allows systems to perform at its highest efficiency. Philips founded a technology that reduces the mercury level of the lamps, which as a result has meant that Phillips bulb contain the lowest amount of mercury in the industry.

Quartz Sleeve

The quartz sleeve in your IWE UV is a made from high quality industrial technology glass, which has substantial and chemical properties. Your quartz sleeve can stop a spectrum transmission less than 220 nm and prevent any radiation of high-density UV rays and will not generate an ozone. UV transmissions can be steralised effectively at 254nm which is more than 95%. The IWE UV quartz sleeve has a high temperature and corrosion resistance, high performance of electrical insulation, long life, > 95% of visible light transmittance and > 99.99% high purity of silicon dioxide.

Typical Installation of your IWE UV

One-year guarantee

For more information contact one of our sales team on: sales@industrialwaterequipment.co.uk

[/three_fourth_last]