You are here : Home | Products & Systems | Water Leak Detection Equipment | Comms Room Product Data

Leak Detection Units – Comms Room Product Data

| Comms Room Leak Detection | Product Data |

[two_third]

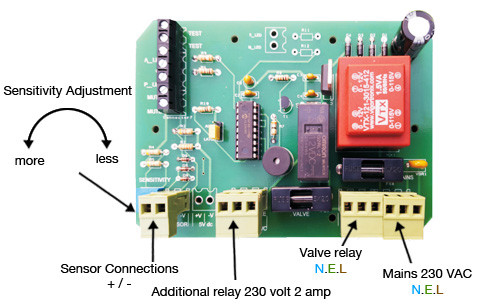

The Leak-Stop detects the presence of water in environments where it shouldn’t be. Perfect for use in tea points, WC areas, smaller comms rooms and plant rooms. If waters detected the alarm panel will trigger an internal buzzer and an LED will start to flash. There is also valve switching as standard and a second volt free relay that will switch when water has been detected.

OUTPUTS ARE AVAILABLE

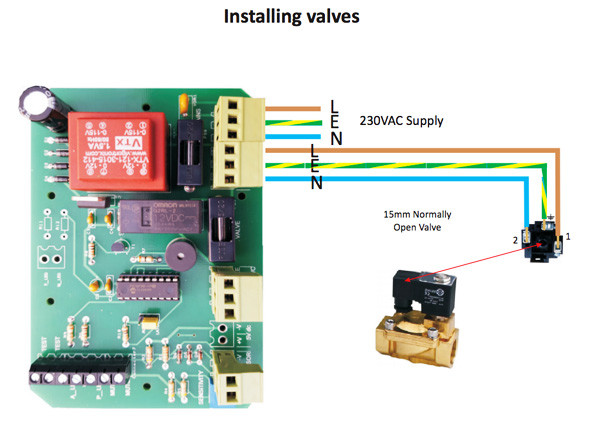

- 1 x dedicated relay for connection to solenoid shut-off valve.

- 1 x 8 amp Volt free changeover common alarm relay, ideal for connection to a BMS.

- Mute button silences the panel after an alarm has been triggered as well as used to reboot the panel should a fault occur.

- Onboard LED output for System Healthy/Power On and Water Leak Detected. (LeakStop +) LED output for cable fault alert.

Quick Start Guide

Trouble Shooting Guide

| PROBLEM | SOLUTION |

| System shows a leak detected, but no water leak is present: | Is the sensor tape/probe used touching anything conductive. |

| Is the sensor tape being used coiled up with the conductor making contact with itself on itself. | |

| Is the combined tape and connection cable length more than 100m. | |

| Is there any contamination or debris on the cable/probe. | |

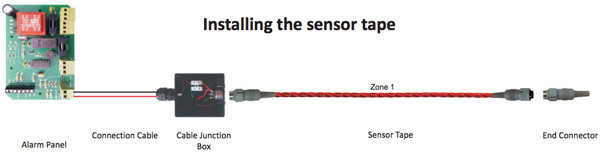

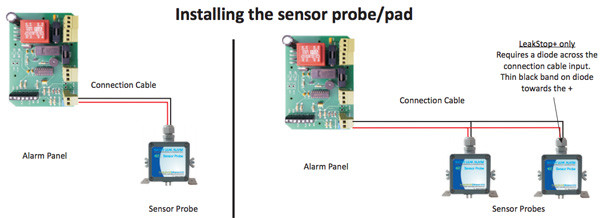

| System shows a line fault: | Is there a diode installed at the end of the cable runProbe, either in the end of line connector at the end of the sensor tape or in the sensor device at the end of the cabling. |

| Are there any breaks in the cable. | |

| Are all the connectors correctly connected. | |

| To assess where the fault is, put a diode in the sensor terminals to see if the problem goes away, if it does the panel is working correctly and the problem is somewhere on the cable run. If the problem is somewhere on the connection cable or sensor tape, try the following: Take the end of line (EOL) connector from the end of the cable run, remove the sensor tape from the junction box and plug the EOL into it. If the problem disappears, this indicates the issue is with the sensor tape. If the problem persists, the issue is either on the connection cable or in the junction box. |

|

| System shows no power: | Is there an appropriate supply to the panel. |

| Is the wiring to the panel sound and secure | |

| Is the L/N/E connected to the correct terminals. |