HOME | STORAGE TANKS

Storage Tanks

We pride ourselves on our “one stop shop” strategy for all types of water treatment equipment and services. Our ever growing range of water storage tanks compliments this strategy with an incredible range of storage systems and accessories.

Our range of water storage tanks include;

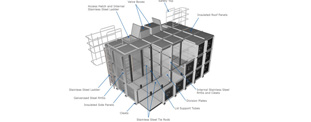

Flat bottomed duel laminate tanks, Thermoplastic water tanks with a choice of conical, flat or sloped bottoms. GRP Storage tanks including GRP sectional tanks incorporating our bespoke sectional tank systems.

We also stock a full range of Bunded Water Storage Tanks, Baffled Water Tanks, Jumbo rotationally moulded storage tanks, Brine tanks and Salt Saturators for Water Softeners, Break Tanks to comply with current regulations and Bunded Water Storage Tanks.

Should you require installation we have a team of experienced engineers based throughout the UK who will be able to come to site, install and commission any of our Storage Tank range for you.

Industrial Water Equipment also offer a fully bespoke storage tank manufacturing service where we can manufacture any size water or chemical tank out of any material. We also clean, chlorinate, reline, refurbish and decommission storage tanks and storage tank systems.

60 to 99 ltr

100 to 199 ltr

200 to 299 ltr

300 to 399 ltr

400 to 499 ltr

500 to 599 ltr

600 to 699 ltr

700 to 799 ltr

800 to 999 ltr

1000 to 1199 ltr

1200 to 1499 ltr

1500 to 1999 ltr

2000 to 2999 ltr

3000 to 3999 ltr

4000 to 5499 ltr

5500 to 5999 ltr

6000 to 6999 ltr

7000 to 7999 ltr

8000 to 8999 ltr

9000 to 9999 ltr

10,000 to 11,999 ltr

12,000 to 14,999 ltr

15,000 to 16,999 ltr

20,000 to 24,999 ltr

Over 25,000 ltr